Check Out Some of Our Work Pictures at these Customer Locations!

Preparation to freeze the 16" Chill Water Pipe

Preparation to freeze the 16" Chill Water Pipe 2

Frozen pipe to shut off water and do the emergency repair

Repairing 16" chill pipe without draining the system

Out with the old gate valves - Dallas Convention Center

In with new butterfly valves - Dallas Convention Center

Dallas Convention Center 1

Dallas Convention Center 3

This is replacing 12 inch gate valves with butterfly valves for increased reliability

This is replacing 12 inch gate valves with butterfly valves for increased reliability

This is replacing 12 inch gate valves with butterfly valves for increased reliability

Another view of replacing 12 inch gate valves with butterfly valves

This is a broken cooling tower shaft at the Dallas convention center

Another view of a broken cooling tower shaft at the Dallas convention center

This is the repair of the broken cooling tower shaft at the Dallas convention center

Gear box oil change with synthetic oil on the cooling tower at convention center

Fixing a refrigerant leak on a walk in cooler condenser

Control Panel work

Changing out a package unit

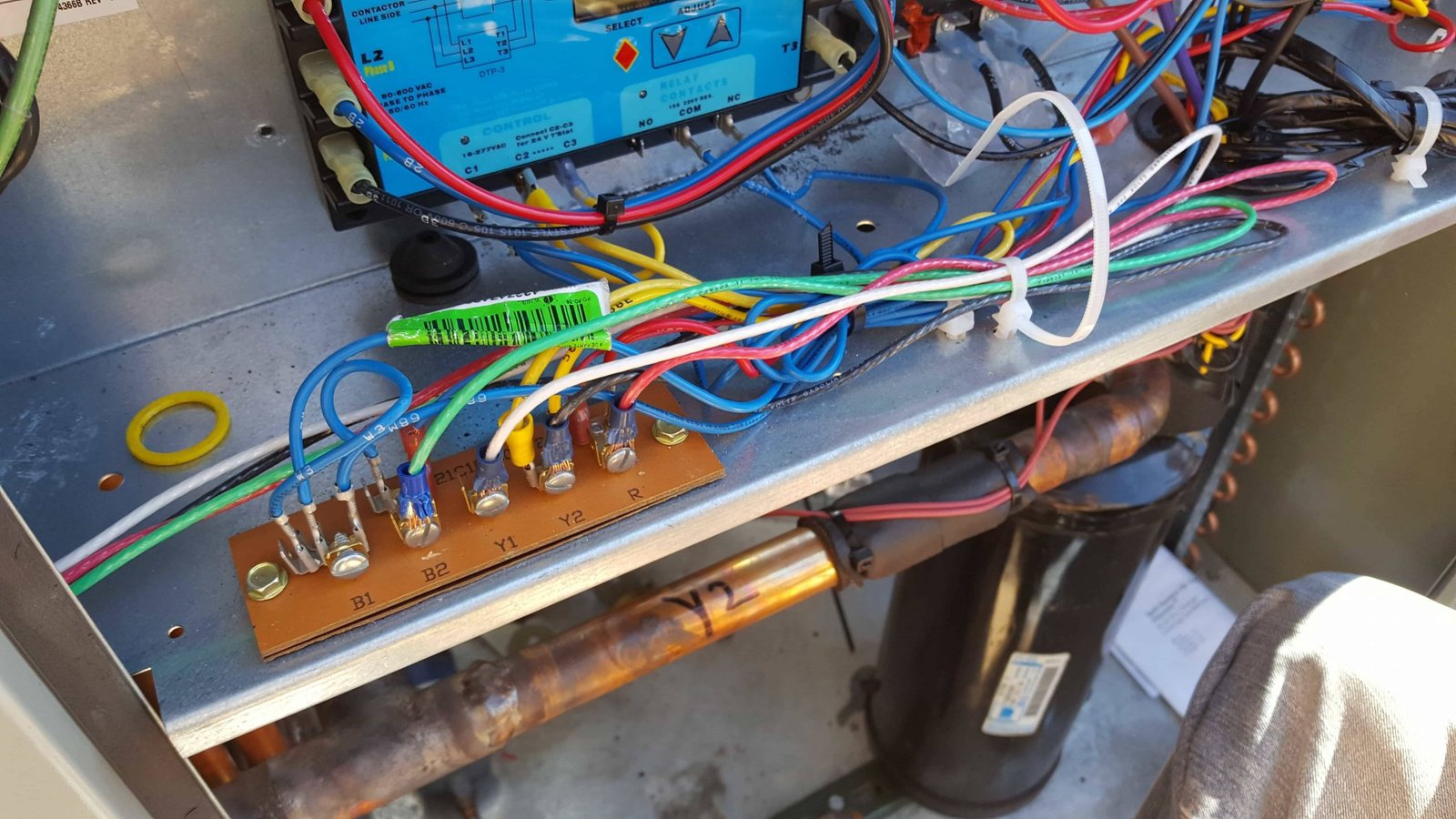

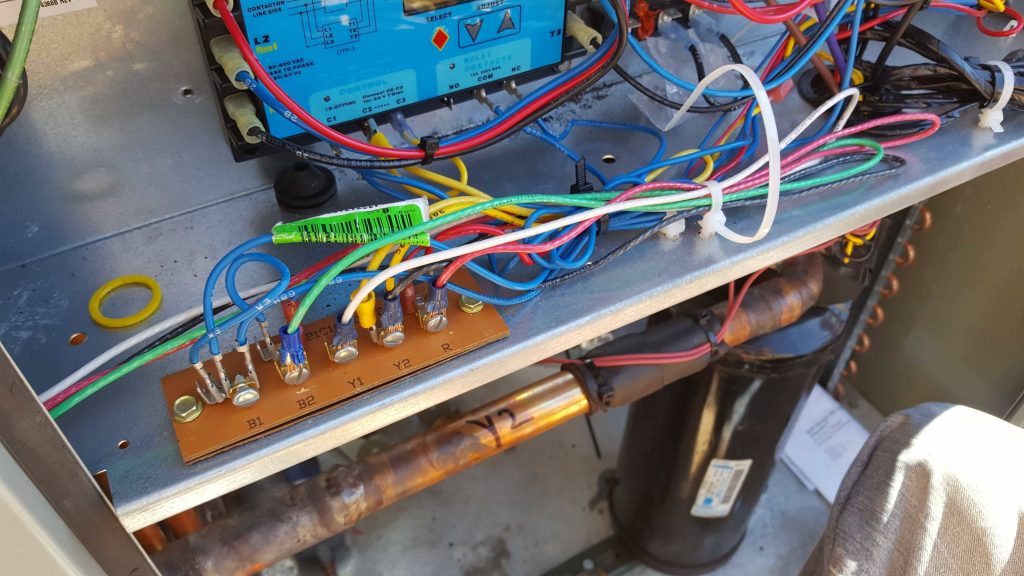

Doing wiring and refrigerant piping for a condenser change out.

Rebuilding a chiller from the 1960s

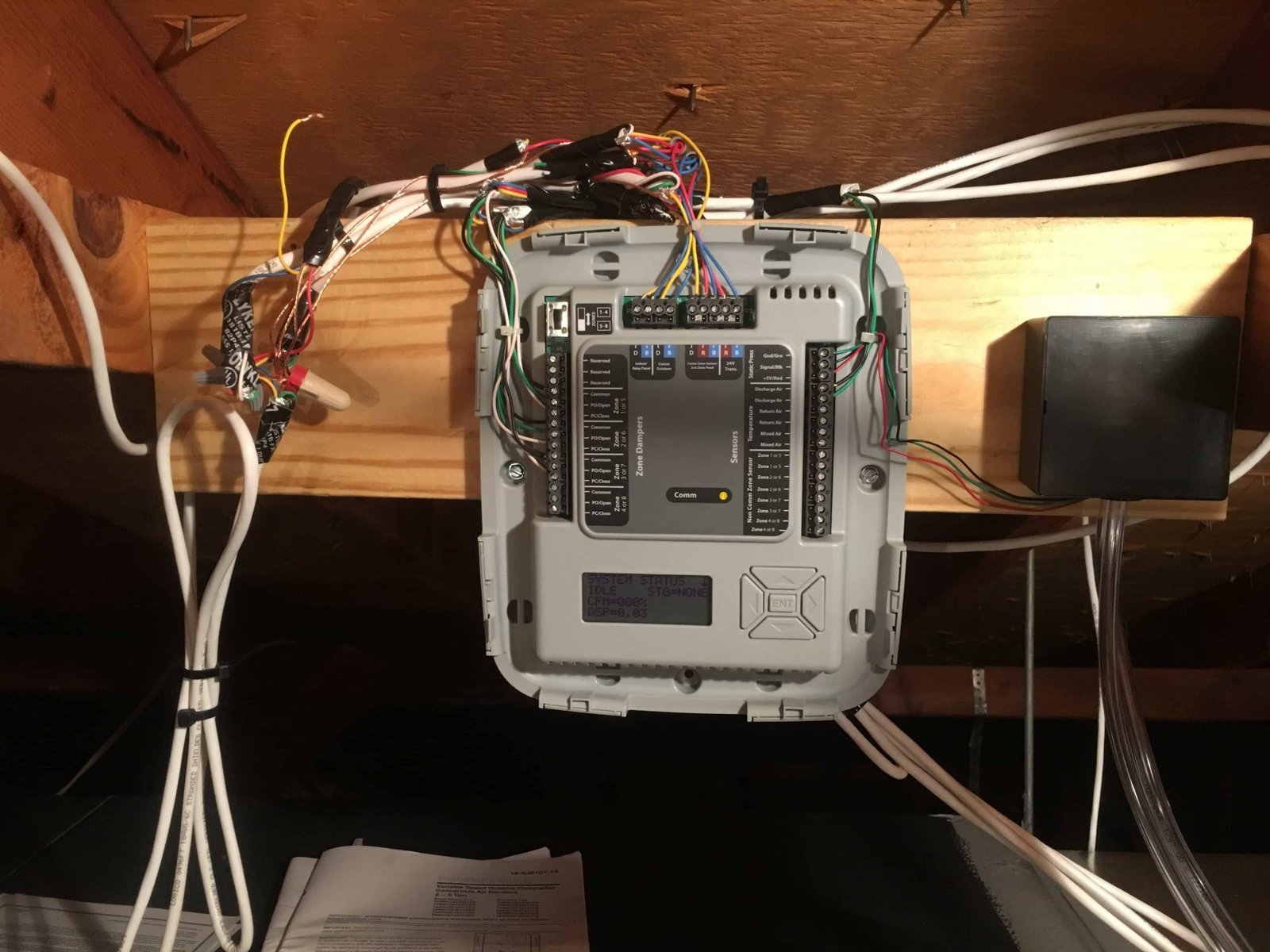

Installing a zoning panel

Installing new electrical service to two new condensers

Working on cooling towers

Starting up a new condenser

Installing new condenser coils in a chiller

PM'ing a refrigerated warehouse

Changing a 40 ton compressor

Luxury cellar of prestigious house, shelves full of bottles

Installation of a new condenser

New chiller ready for setting

Installation of a zone damper

Removing the pump and impeller to change shaft seals and re installing the pump.

HVAC Compressor work

Work at a local brewery

Work at a local brewery

Work at a local brewery

Work at a local brewery

Working on a chiller control cabinet

OUR PROCESS

With every service call or project, our factory trained and professional technicians will thoroughly inspect and diagnose your situation for problems, consult with you on the course of action that works best for you, and make necessary repairs in a timely manner so you can avoid interruptions in service. We make sure to keep you in the loop every step of the way so you have peace of mind and avoid headaches for you and those you work with.

WHY CHOOSE B.I.M.S., Inc.?

B.I.M.S., Inc. has served the Dallas Texas and surrounding areas for over 40 years — we can handle the design, installation, repair and maintenance of Chillers, Boilers, Controls, VFDs, Pumps, Air Conditioning, Heating, Refrigeration, Process cooling and more.

Call us if you have any questions, and schedule a service call or consultation today.